INNOVATIONS

Our company is in the process of constant innovation development of technologies and equipment. Close cooperation with leading manufacturers of injection molding machines and peripheral equipment, as well as additives based on PET, allow us to meet any customer needs in the production of PET preforms.

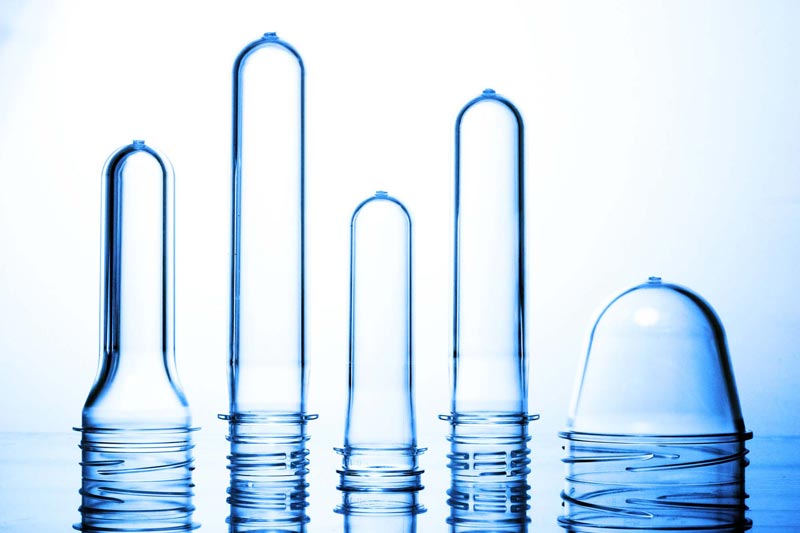

Using the most advanced high-tech equipment that works with the use of energy saving technologies, we are able to produce goods for our clients:

– PET preforms with lower level of heating in the furnace, with functions of product protection from ultraviolet (UV), barrier properties to resist oxidation by oxygen and resistance to loss of carbon dioxide (CO2), low coefficient of friction, with the application of antistatic agents, with lower content of acetaldehyde (AA) in PET, antimicrobial and antioxidant properties, increase of product shelf-live in our packaging in 2-3 times by supplementation with increased barrier properties;

– PET preforms using RePET for those who are actively involved in the environmental programs on the protection from contamination;

– PET preforms produced from raw materials made using ethanol, obtained in the processing of plant materials (sugar cane, maize) that are to be subsequently recycled after use;

– PET preforms for decorative bottles with dyes, additives, giving the effect of bubbles, frost, etc. to the final product (bottle).